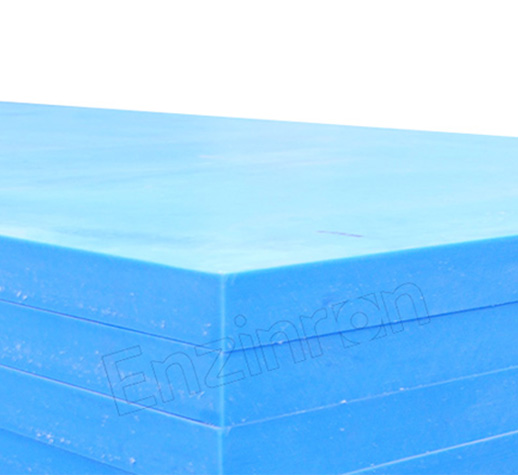

MC nylon

Casting Nylon

MC Is Cast Nylon, Higher Toughness Than Ordinary Nylon, Good Flexibility, Fatigue Resistance, Is The Ideal Material For Gears, Racks And Transmission Gears.

Advantage

Characteristic:

Mechanical Strength, Stiffness, Hardness, Toughness, Good Aging Resistance, Good Mechanical Vibration Damping Ability, Good Sliding Property, Excellent Wear Resistance, Good Machining Performance, Used For Precision And Effective Control, No Creep Phenomenon, Good Wear Resistance, Good Dimensional Stability.

Information

| Shape | Colour | ||||||

|  | ||||||

| Plate | Bar | Black | Yellow | Blule | Green | Red | True Color |

| Thickness(mm) | Breadth(mm) | Length(mm) |

| 6-200 | 1000 | 2000 |

| Diameter(mm) | Length(mm) |

| 6-150 | 1000 |

Tensile strength | GB/T 1040 | MPa | 75-85 |

Modulus of elongation | ISO 527 | Mpa | 4100 |

Elongation at break | ISO 527 | % | >25 |

Maximum compressive strength | ISO 604 | Mpa | 90-100 |

Coefficient of compression | ISO 604 | Mpa | 2700 |

Bending strength | ISO 178 | MPa | 100-110 |

Elastic bending coefficient | ISO 178 | MPa | 3300 |

Shore hardness | GB/T 2411 | D | 83 |

Fusing point | ISO | °C | 220 |

Maximum intermittent service temperature | ASTM D648 | °C | 180 |

Minimum continuous operating temperature | - | °C | 115 |

Maximum operating temperature | - | °C | -100 |

Minimum continuous operating temperature | - | °C | -40 |

Coefficient of linear expansion | ISO 11359 | 10-5-1/K | 5-8 |

Dielectric constant | IEC 250 | - | 3.7 |

Dielectric strength | IEC 243 | KV-mm | >25 |

| Volume resistivit | IEC 93 | Ω.cm | 1015 |

Surface resistivity | IEC 93 | Ω | 1015 |

Impedance | IEC 112 | - | CT1600 |

combustibility | UL 94 | V-0 | |

Abrasion resistance | - | + | |

Friction coefficient | EEC 90/128 FDA | + |